Understanding Strain Wave Gears How They Work and Their Applications

In the realm of precision machinery, strain wave gears have emerged as a pivotal technology due to their unique design and functionality. Renowned expert Dr. Emily Harris, a leading figure in mechanical engineering, notes, "Strain wave gears enable high torque density and extraordinary precision, making them invaluable in advanced robotics and aerospace applications." This innovative gearing system utilizes the principles of elastic deformation to achieve higher efficiency and compactness, setting a new standard in various industries.

The working principle of strain wave gears revolves around the deformation of a flexible spline driven by an elliptical disc, creating a highly efficient and backlash-free motion transmission. As industries increasingly demand enhanced performance and reliability, these gears are becoming essential components in applications ranging from robotic arms to space exploration vehicles. Their ability to manage high loads while maintaining a low profile highlights the technical mastery that defines modern engineering solutions.

As we delve deeper into understanding strain wave gears, we will explore their operational mechanisms, distinctive advantages, and burgeoning applications across various sectors. This exploration will shed light on why strain wave gear systems are not only revolutionizing mechanical design but also paving the way for future technological advancements.

What Are Strain Wave Gears and Their Key Components

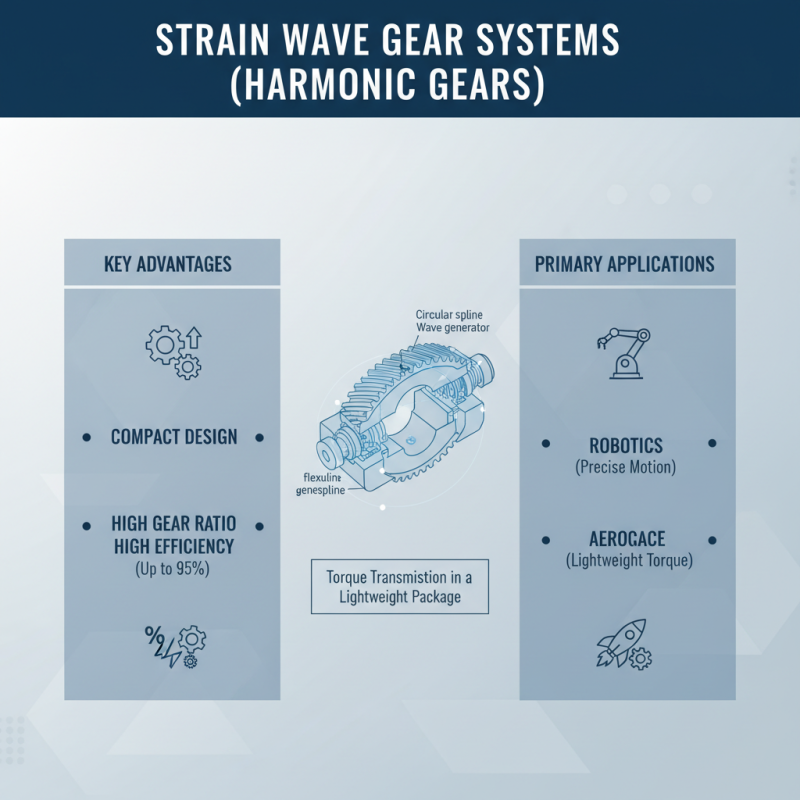

Strain wave gears, also known as harmonic drives, are a unique type of gear system that leverages the principles of strain wave deformation to achieve high precision and compact design. Unlike traditional gears, which rely on direct meshing, strain wave gears work on the principle of elastic deformation. The primary components include a wave generator, anflex spline, and a circular spline. The wave generator produces an elliptical motion that causes the flex spline to deform and engage with the circular spline at different positions, allowing for high reduction ratios and minimal backlash.

According to a report by Research and Markets, the global harmonic drive market is projected to grow from approximately $1.1 billion in 2021 to over $1.5 billion by 2026, evidencing their increasing importance across various industries. This growth is largely driven by their applications in robotics, aerospace, and industrial automation, where precision and compactness are critical. Strain wave gears are particularly favored in robotic joints, where they provide the necessary torque and motion control with reduced size and weight, thus enhancing the overall efficiency and performance of robotic systems.

In addition, the ability of strain wave gears to offer high torque density—up to five times more than traditional gear systems—has made them a go-to solution for applications requiring both strength and compactness. This attribute is invaluable in fields such as medical devices and satellite technology, where space is often at a premium, but reliability and precision remain paramount. As engineering demands continue to evolve, the unique design and capabilities of strain wave gears are likely to lead the way in innovative gear solutions.

The Working Principle of Strain Wave Gears Explained

Strain wave gears, also known as harmonic drives, function based on the unique mechanics of strain wave deformation. They consist of three primary components: a circular splined input, a flexible spline that deforms to fit inside the output, and an output gear with fixed teeth. When the input shaft rotates, it causes the flexible spline to flex and engage with the teeth of the output gear. This engagement transfers motion and magnifies torque, allowing for high gear reduction ratios in a compact design. The simplicity of this mechanism enables precise motion control, making it ideal for applications requiring high accuracy.

Tips: When considering strain wave gears for your project, it's crucial to evaluate the specific torque requirements and space constraints. Their compact nature is an advantage, but it also means that optimal sizing is vital for performance. Be aware of potential backlash issues and ensure that the installation process adheres to manufacturer specifications for maximum efficiency.

Moreover, strain wave gears are increasingly utilized in robotics, aerospace, and medical devices where reliability and precision are paramount. Their ability to deliver high torque in tight spaces makes them a perfect fit for robotic limbs and aerospace actuators. By understanding their working principle, engineers can better incorporate these gears into innovative designs, enhancing the functionality and performance of complex systems.

Understanding Strain Wave Gears: Applications and Efficiency

Advantages and Limitations of Strain Wave Gear Systems

Strain wave gear systems, also known as harmonic gears, stand out in various applications for their unique advantages and limitations. One significant advantage is their high gear reduction ratio within a compact design, which can reach up to 100:1 in a single stage. According to a recent industry report, these gears offer efficiencies of up to 95%, making them suitable for applications requiring precise motion control, such as robotics and aerospace systems. The ability to transmit torque in a lightweight package is invaluable in modern engineering, especially in sectors demanding efficiency and reduced weight.

However, strain wave gears come with limitations that must be considered. Their design and operational principles lead to a lower load capacity compared to traditional gear systems, making them less suitable for heavy-duty applications. Additionally, the complexity of their construction can result in higher manufacturing costs, which may not always be justifiable in budget-sensitive projects. It's essential to weigh these factors carefully when selecting a gear system for specific tasks.

Tips: When considering a strain wave gear for your project, it’s crucial to calculate the required torque and operational life of the gear to ensure it aligns with your engineering needs. Also, keep an eye on new advancements in gear technology, as innovations could enhance the performance and cost-effectiveness of strain wave gear systems in the near future. Always consult with technical experts to find the best fit for your application.

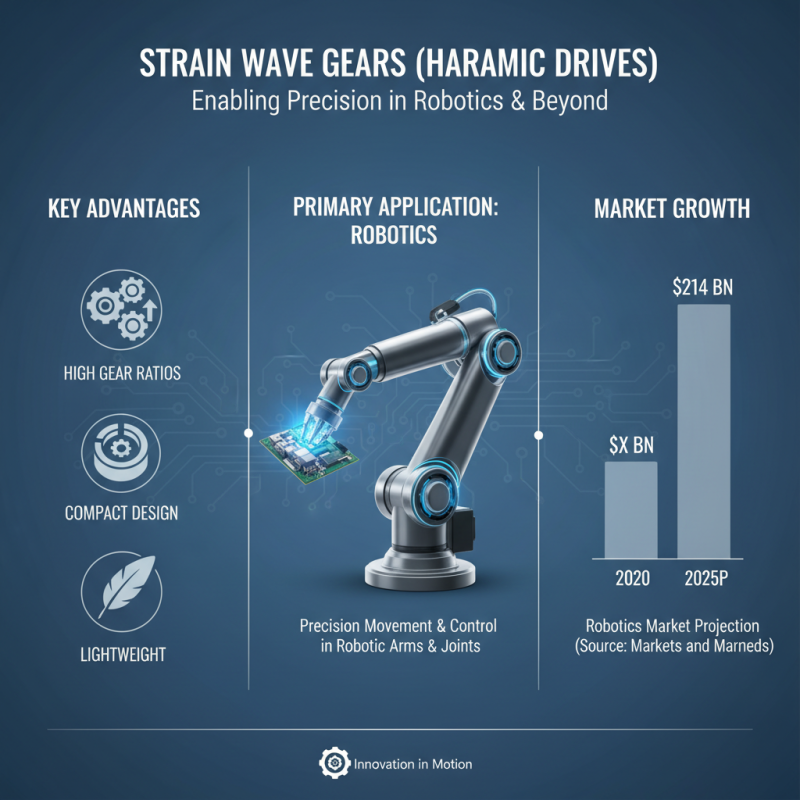

Common Applications of Strain Wave Gears in Various Industries

Strain wave gears, also known as harmonic drives, have gained significant traction across various industries due to their unique advantages, such as high gear ratios, compact designs, and lightweight properties. One of the most notable applications of strain wave gears is found in robotics, where they facilitate precision movement and control in robotic arms and joints. According to a report by Markets and Markets, the robotics market is projected to reach $214 billion by 2025, highlighting the importance of efficient and reliable transmission systems like strain wave gears in meeting the increasing demand for advanced robotic solutions.

In the aerospace industry, strain wave gears are utilized in guidance and stabilization systems for spacecraft and satellites. Their ability to handle high torque with minimal backlash is crucial in applications that require accurate positioning, such as in antenna deployments or solar panel adjustments. The global aerospace market, projected to be valued at over $800 billion by 2028, emphasizes the need for innovative technologies like strain wave gears that can support next-generation aerospace applications and ensure mission success under extreme conditions.

Additionally, the medical equipment sector has begun to adopt strain wave gears in devices that necessitate careful movement and precision, such as surgical robots and imaging equipment. The global medical robotics market is expected to exceed $20 billion by 2026, driven by the rising demand for minimally invasive procedures. Strain wave gears contribute significantly to this trend, providing the reliability and precision needed for complex surgical tasks, ultimately improving patient outcomes and operational efficiencies in medical environments.

Future Trends and Developments in Strain Wave Gear Technology

The ongoing advancements in strain wave gear technology are poised to significantly impact various industrial applications, especially in robotics and aerospace. Recent market analysis reports indicate that the global strain wave gear market is expected to grow at a compound annual growth rate (CAGR) of approximately 6.8% from 2023 to 2030. This growth is driven by the increasing demand for precision motion control systems, where strain wave gears excel due to their high torque density and compact design. Internally, the structural improvements in gear manufacturing, such as the adoption of advanced materials and computer-aided design techniques, contribute to enhancing gear performance and extending service life.

Future developments are likely to focus on improving the efficiency and load capacity of strain wave gears, enabled by innovations in materials science and manufacturing technologies. The integration of smart sensors and IoT connectivity is also anticipated to revolutionize how strain wave gears operate, allowing for real-time monitoring and predictive maintenance. These advancements could provide businesses in automation and robotics with higher reliability and efficiency, ultimately reducing downtime and operational costs.

As these technologies mature, we can expect to see strain wave gears becoming an integral part of more complex and demanding applications, solidifying their place in the future of precision engineering.