Why Choosing the Right Gear Reducer is Essential for Your Mechanical Efficiency

In the realm of mechanical engineering, the choice of a gear reducer is pivotal for optimizing performance and ensuring energy efficiency. According to a report by the International Journal of Mechanical Engineering Research, inefficiencies in power transmission can lead to energy losses of up to 20% in industrial applications. This statistic underscores the importance of selecting the right gear reducer, as it directly impacts operational costs and overall productivity.

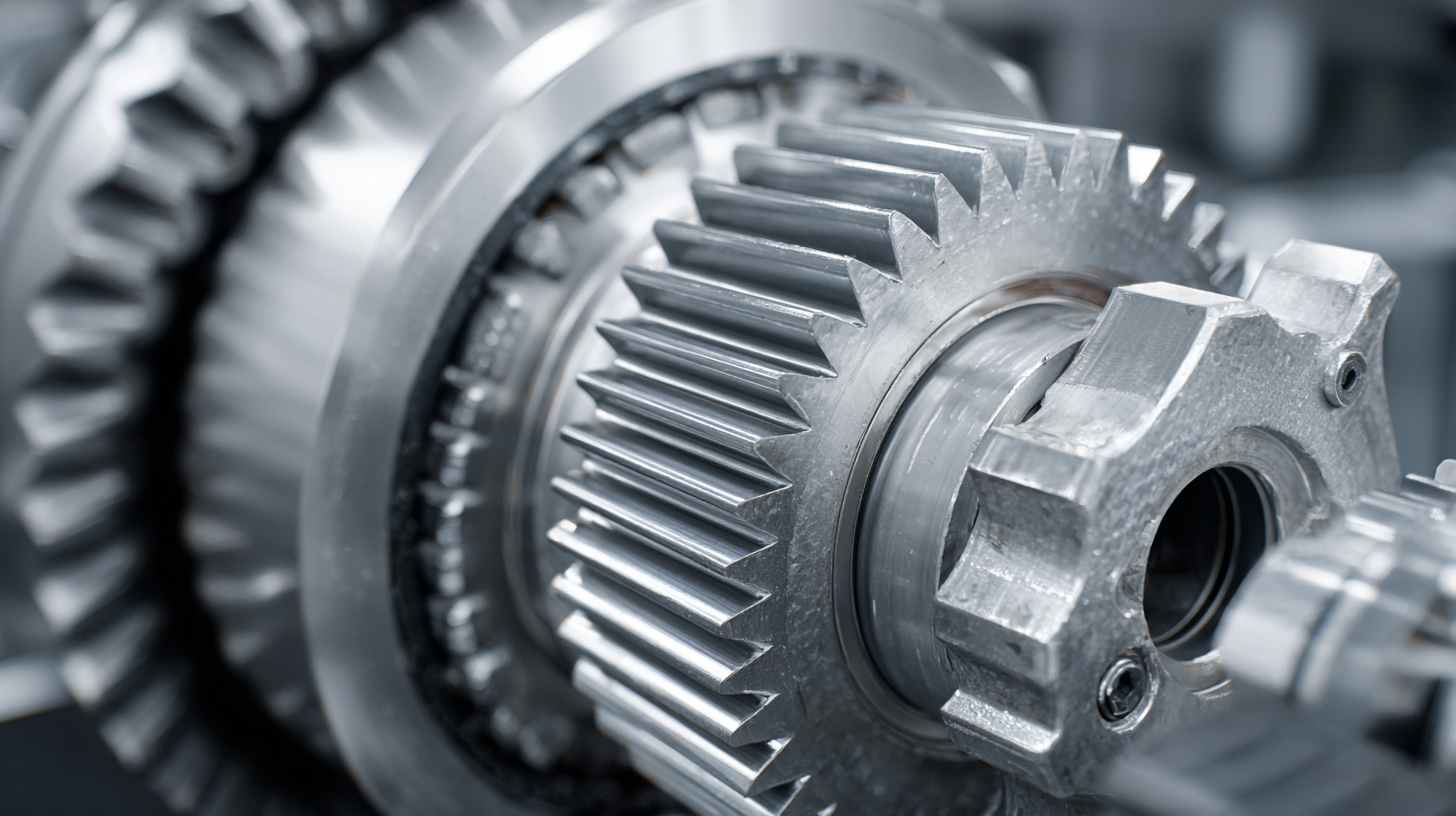

Gear reducers play a crucial role in adjusting speed and torque within machinery, making it essential to match their specifications to the specific requirements of the application. In this guide, we will explore how selecting the appropriate gear reducer can maximize mechanical efficiency, enhance durability, and minimize downtime in various industries, emphasizing the need for informed decision-making in gear reducer selection.

Understanding Gear Reducers: Types and Applications in Mechanical Systems

Gear reducers play a crucial role in enhancing the efficiency of mechanical systems by adjusting the output speed and torque generated by motors. There are several types of gear reducers, including worm gear reducers, helical gear reducers, and planetary gear reducers, each offering unique advantages based on specific applications. For instance, worm gear reducers are favored for their compact design and high torque multiplication, making them suitable for applications requiring significant reduction ratios and high load capacities. On the other hand, helical gear reducers are recognized for their smooth operation and efficiency, often used in industries such as automotive and manufacturing where reliability and performance are paramount.

Gear reducers play a crucial role in enhancing the efficiency of mechanical systems by adjusting the output speed and torque generated by motors. There are several types of gear reducers, including worm gear reducers, helical gear reducers, and planetary gear reducers, each offering unique advantages based on specific applications. For instance, worm gear reducers are favored for their compact design and high torque multiplication, making them suitable for applications requiring significant reduction ratios and high load capacities. On the other hand, helical gear reducers are recognized for their smooth operation and efficiency, often used in industries such as automotive and manufacturing where reliability and performance are paramount.

Applications of gear reducers span across various sectors, from conveyor systems in material handling to robotics and automation. Each application demands a specific type of gear reducer tailored to its operational needs. Planetary gear reducers, known for their multi-gear configuration, are particularly effective in applications that require high efficiency and minimal backlash, such as precision machinery. Understanding these varying types and their applications enables engineers and designers to make informed decisions when selecting the right gear reducer, thereby optimizing the overall mechanical efficiency of their systems.

The Role of Gear Reducers in Enhancing System Efficiency and Performance

Gear reducers play a crucial role in enhancing system efficiency and performance across various mechanical applications. By reducing the speed of a motor while increasing torque, these devices allow machinery to operate at optimal levels without excessive energy consumption. The right gear reducer can significantly improve the reliability and longevity of equipment, ensuring smooth and consistent operation in challenging environments.

When selecting a gear reducer, consider the specific requirements of your application. Factors such as the load capacity, input speed, and desired output torque should all influence your decision. Ensuring compatibility with existing systems can prevent operational inefficiencies and potential damage.

**Tips:** Always consult with a specialist to determine the best gear reducer for your needs. Regular maintenance and monitoring of the gear reducer can catch any issues early, ensuring that your mechanical systems continue to run efficiently. Lastly, keep an eye on the performance metrics of your machinery; this data can provide insights into whether your current gear reducer is meeting operational demands effectively.

Key Factors to Consider When Selecting Gear Reducers for Industrial Use

When selecting gear reducers for industrial applications, several key factors must be taken into account to ensure mechanical efficiency. According to a report from the International Gearbox Manufacturer’s Association, improper gear selection can reduce operational efficiency by as much as 30%. The first factor to consider is the gear ratio, which affects output speed and torque. An optimal gear ratio not only maximizes performance but also extends the lifespan of machinery by minimizing wear and tear.

Another critical element is the overall efficiency rating of the gear reducer, often represented as a percentage. According to the American Association of Mechanical Engineers, gear reducers with an efficiency rating of 95% or higher can significantly reduce energy consumption, resulting in lower operational costs. Additionally, assessing the load capacity is essential. Selecting a gear reducer that adequately supports the expected load ensures reliability and performance stability, preventing costly downtimes. Therefore, thorough analysis of gear specifications, including efficiency, load capacity, and gear ratio, is vital for achieving optimal mechanical performance in industrial settings.

Industry Statistics on Gear Reducers and Their Impact on Energy Consumption

Choosing the right gear reducer is critical for optimizing mechanical efficiency, particularly in light of current industry trends and energy consumption statistics. With a growing emphasis on decarbonization across industrial sectors, selecting high-quality gear reducers can significantly influence energy-related carbon dioxide emissions. Research indicates that efficient gear reducers not only enhance performance but also reduce operational energy costs, aligning with sustainable practices needed to combat climate change.

Recent data reflects a marked trend in industries striving to minimize their carbon footprints. As companies face increasing pressure to improve energy efficiency, the effectiveness of gear reducer technology stands out as a pivotal factor. The integration of advanced gear reducers in manufacturing processes can lead to substantial reductions in energy consumption and emissions, ultimately fostering a shift towards more sustainable industrial practices. This alignment with energy management strategies is essential for businesses aiming to navigate the challenges of both economic viability and environmental responsibility.

Why Choosing the Right Gear Reducer is Essential for Your Mechanical Efficiency

| Gear Reducer Type |

Efficiency (%) |

Energy Consumption (kWh) |

Cost ($) |

Application |

| Helical Gear Reducer |

95 |

120 |

800 |

Automotive |

| Planetary Gear Reducer |

98 |

100 |

1200 |

Aerospace |

| Worm Gear Reducer |

90 |

150 |

700 |

Food Processing |

| Bevel Gear Reducer |

92 |

130 |

850 |

Material Handling |

Case Studies: Successful Implementations of Gear Reducers in Various Industries

In various industries, the implementation of gear reducers has significantly enhanced mechanical efficiency and operational productivity. For instance, a case study in the automotive sector demonstrated that by integrating high-efficiency gear reducers, manufacturers were able to increase assembly line speeds by approximately 15%. The report from the International Society of Automation noted that optimized gear reduction systems played a critical role in achieving these improvements, allowing for smoother operations and reduced energy consumption.

Similarly, in the renewable energy sector, specifically wind turbine installations, the adoption of advanced gear reducers resulted in a noteworthy reduction of mechanical losses. According to a study published by the American Wind Energy Association, turbines equipped with high-performance gear reducers experienced an increase in energy output of up to 10%, directly correlating with enhancements in gear design and materials used. This highlights the importance of selecting the right gear reducer, as it not only boosts efficiency but also maximizes the overall performance of machinery across different applications.

Gear reducers play a crucial role in enhancing the efficiency of mechanical systems by adjusting the output speed and torque generated by motors. There are several types of gear reducers, including worm gear reducers, helical gear reducers, and planetary gear reducers, each offering unique advantages based on specific applications. For instance, worm gear reducers are favored for their compact design and high torque multiplication, making them suitable for applications requiring significant reduction ratios and high load capacities. On the other hand, helical gear reducers are recognized for their smooth operation and efficiency, often used in industries such as automotive and manufacturing where reliability and performance are paramount.

Gear reducers play a crucial role in enhancing the efficiency of mechanical systems by adjusting the output speed and torque generated by motors. There are several types of gear reducers, including worm gear reducers, helical gear reducers, and planetary gear reducers, each offering unique advantages based on specific applications. For instance, worm gear reducers are favored for their compact design and high torque multiplication, making them suitable for applications requiring significant reduction ratios and high load capacities. On the other hand, helical gear reducers are recognized for their smooth operation and efficiency, often used in industries such as automotive and manufacturing where reliability and performance are paramount.