How to Choose the Right Worm Gear Reducer for Your Application?

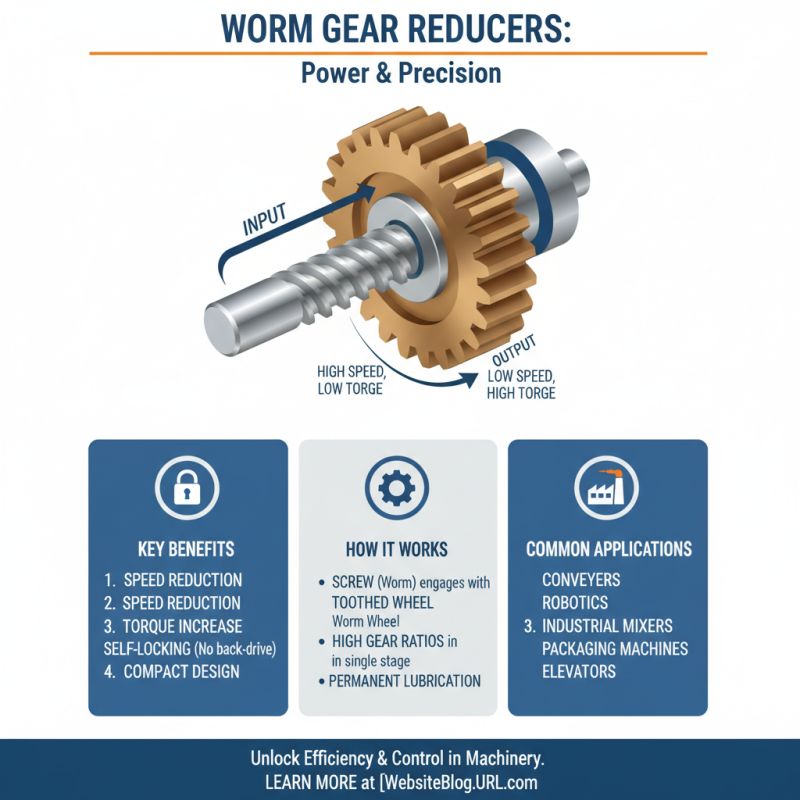

Choosing the right worm gear reducer is crucial for many applications. A worm gear reducer offers unique advantages, such as high torque and compact design. These features make them suitable for various industries, including manufacturing and robotics.

When selecting a worm gear reducer, consider factors like load capacity and speed reduction. The right choice impacts overall efficiency. Small miscalculations can lead to performance issues later. You must evaluate your specifications carefully.

Visualizing your application's needs is essential. Imagine a conveyor system needing precise control; a well-chosen worm gear reducer can enhance productivity. However, overlooking compatibility may result in inefficiency. Finding the ideal match requires careful thought and testing.

Understanding Worm Gear Reducers and Their Applications

Worm gear reducers are essential tools in various applications. They provide speed reduction and torque increase in machinery. Understanding their design helps in making informed choices. A worm gear consists of a screw (the worm) and a gear (the worm wheel). This unique interaction allows for significant speed changes.

When selecting a worm gear reducer, consider the load requirements. Think about the operating environment as well. High temperatures can affect performance. Corrosive environments may require special materials. If these factors aren't assessed, you might face issues later.

Tips for choosing: Look for efficiency ratings. They will impact overall performance. Check for backlash specifications too. Excessive backlash can cause mechanical problems. Don’t forget to analyze noise levels. Loud gearboxes can indicate underlying issues. Take your time to review every detail before deciding.

Key Considerations for Selecting a Worm Gear Reducer

Choosing the right worm gear reducer can feel overwhelming. There are many factors to consider. The application’s torque and speed requirements are crucial. Too little torque, and your machinery may fail. Too much, and you risk damaging the gear. Always calculate these values accurately.

Size and space constraints also play a significant role. Does the equipment have enough room for installation? Consider the orientation of the reducer as well. Some applications may favor a horizontal position, while others do not. Remember, an ill-fitted reducer leads to inefficiency.

Material selection deserves attention, too. Metals like bronze and aluminum are common choices. Each material has its benefits and drawbacks. For instance, aluminum is lightweight, yet it may not withstand extreme conditions. You’ll also need to reflect on the environment where the reducer will operate. Is it dusty? Wet? These factors will influence maintenance needs and durability.

Evaluating Load Requirements and Performance Specifications

Choosing the right worm gear reducer begins with understanding your application's load requirements. Consider the type of load—whether it is dynamic or static. Dynamic loads change over time, while static loads remain constant. This distinction affects the reducer's design and performance.

Performance specifications are equally essential. Look at the torque and speed ratings. Ensure your chosen reducer can deliver the required torque without overheating. Pay attention to the gear ratio as well. A higher ratio means more torque but less speed. Finding the right balance is key.

**Tip:** Always test your equipment under real conditions. Performance can change with varying loads. Take time to analyze how your reducer handles different stresses.

**Tip:** Don’t overlook adjustments. Sometimes, minor tweaks can lead to significant performance improvements. Consider feedback from operators who use the equipment daily. Their insights can guide you in making the right decision.

How to Choose the Right Worm Gear Reducer for Your Application?

| Dimension |

Specification |

Example Value |

| Gear Ratio |

The ratio of the input speed to the output speed |

10:1 |

| Load Capacity |

Maximum load the reducer can handle |

500 Nm |

| Efficiency |

Energy efficiency rating of the gear reducer |

90% |

| Noise Level |

Operating sound level during usage |

60 dB |

| Input Speed |

Speed of the motor driving the reducer |

1500 RPM |

| Output Torque |

Torque available at the output shaft |

750 Nm |

| Material |

Material used for the gear and housing |

Aluminum Alloy |

| Operating Temperature |

Temperature range for optimal operation |

-10°C to 80°C |

Assessing Material and Design Options for Durability

When choosing a worm gear reducer, material selection and design play crucial roles in durability.

Common materials include aluminum, steel, and plastic.

Each has its strengths and weaknesses.

Aluminum is lightweight but may not withstand heavy loads.

Steel offers strength but can rust without proper treatment.

Plastic can be cost-effective but lacks the resilience of metal.

Choosing the right material can prevent future issues.

Design features also impact durability. A well-designed worm gear can reduce friction and heat generation.

Compact designs save space but may compromise cooling. Larger gear housings can dissipate heat better but take up more room.

Consider the application environment. Dusty, wet, or corrosive settings will demand tougher designs.

Sometimes, well-made components fail in harsh conditions if not adequately protected.

Testing the materials under real-world conditions is advisable. Gathering data on performance can help refine your choices.

Look for signs of wear or failure early on. Continuous improvement should be a goal.

No designer gets it right the first time. Embrace feedback and learn from it.

Durability is not just about initial selection; it’s an ongoing process.

Comparing Cost and Maintenance Factors in Worm Gear Reducers

When selecting a worm gear reducer, considering cost and maintenance is crucial. According to industry reports, the average lifespan of worm gear reducers can vary significantly, typically between 15,000 to 20,000 hours. This lifespan can be heavily influenced by proper maintenance. Neglecting regular maintenance can reduce efficiency and lead to replacements sooner than expected.

Maintenance costs can accumulate over time. On average, businesses spend about 2-5% of a reducer’s initial cost annually on maintenance. However, many overlook this aspect until problems arise. Regular oil changes and inspections are essential yet often disregarded. These tasks can prevent unexpected failures and prolong the reducer’s life.

Moreover, the initial cost of worm gear reducers can be misleading. Some high-cost units may offer lower long-term operating expenses. In contrast, cheaper models might attract initial buyers but can have higher maintenance costs. Understanding the true cost of ownership helps in making a more informed decision. Balancing upfront costs and future maintenance is critical for achieving long-term savings and reliability in operations.