How to Choose the Right Filling Machine for Your Business Needs

Choosing the right filling machine is a critical decision for any business involved in manufacturing and packaging products. With a wide variety of filling machines available in the market, each designed for specific applications and functionalities, it can be daunting to identify which option best suits your operational needs. The selection process must take into consideration several factors, including the type of product being filled, the intended production speed, and the desired accuracy of the filling process.

In addition to the technical specifications, businesses must assess their production volume and future scalability when determining the ideal filling machine. Understanding the unique requirements of your products—from liquids and powders to granular substances—will guide you in finding a machine that can efficiently meet your production goals. Moreover, factors such as ease of use, maintenance needs, and overall investment cost can significantly influence your decision. By strategically analyzing these elements, you can choose a filling machine that not only enhances efficiency but also supports your business’s long-term growth and success.

Understanding Different Types of Filling Machines Available in the Market

When selecting a filling machine for your business, understanding the various types available is essential to meet your specific needs. The market offers several categories of filling machines, each designed for different applications. For instance, volumetric filling machines measure product volume to ensure consistent fills. These are commonly used in industries such as food and beverage, where accuracy is crucial for maintaining product quality and compliance with regulations.

Another popular type is gravimetric filling machines, which weigh the product as it's dispensed. This method is beneficial for businesses that deal with products that have varying densities, ensuring that every package contains the precise amount needed. Additionally, there's aseptic filling, which is vital for products requiring sterile conditions, such as pharmaceuticals and certain liquid foods. Understanding these distinctions will help you choose a filling machine that not only fits your production goals but also enhances your operational efficiency while maintaining product integrity.

Assessing Your Business’s Specific Filling Requirements and Goals

Assessing your business's specific filling requirements is crucial for selecting the right filling machine. Understanding the type of products you intend to fill—be it liquids, powders, granules, or pastes—is the first step. According to a report by Smithers Pira, the demand for liquid filling machines is projected to grow at a CAGR of about 4.2% from 2021 to 2026, reflecting a significant transformation in filling technologies driven by consumer preferences and regulatory requirements. Therefore, businesses must evaluate the viscosity and density of their products to ensure compatibility with the machine's specifications.

In addition to product characteristics, businesses should consider their production goals. For instance, if your objective is to enhance efficiency, a machine that offers high-speed filling capabilities may be necessary. Data from the International Packaging Association indicates that companies focusing on automation can reduce operational costs by up to 25% while accelerating throughput. Furthermore, assessing the scale of production—whether you are aiming for small batches or large-scale operations—will determine the required output and type of filling technique, such as volumetric, gravimetric, or time-based filling options. Each of these factors plays a pivotal role in aligning your choice of machinery with your business objectives.

How to Choose the Right Filling Machine for Your Business Needs

| Filling Type |

Suitable Products |

Speed (bottles/min) |

Accuracy (%) |

Special Features |

| Gravity Filling |

Water, Syrup, Wine |

30 |

95 |

Easy to clean, low maintenance |

| Piston Filling |

Thick liquids, Sauces, Pastes |

20 |

98 |

Handles viscosities, adjustable stroke |

| Vacuum Filling |

Carbonated drinks, Liquid food |

25 |

99 |

Reduced oxidation, preserves flavor |

| Screw Filling |

Dry powders, Granules |

15 |

97 |

Minimizes dust, high accuracy |

| Net Weigh Filling |

Bulk materials, Grains |

10 |

99.5 |

Precision weighing, reduces waste |

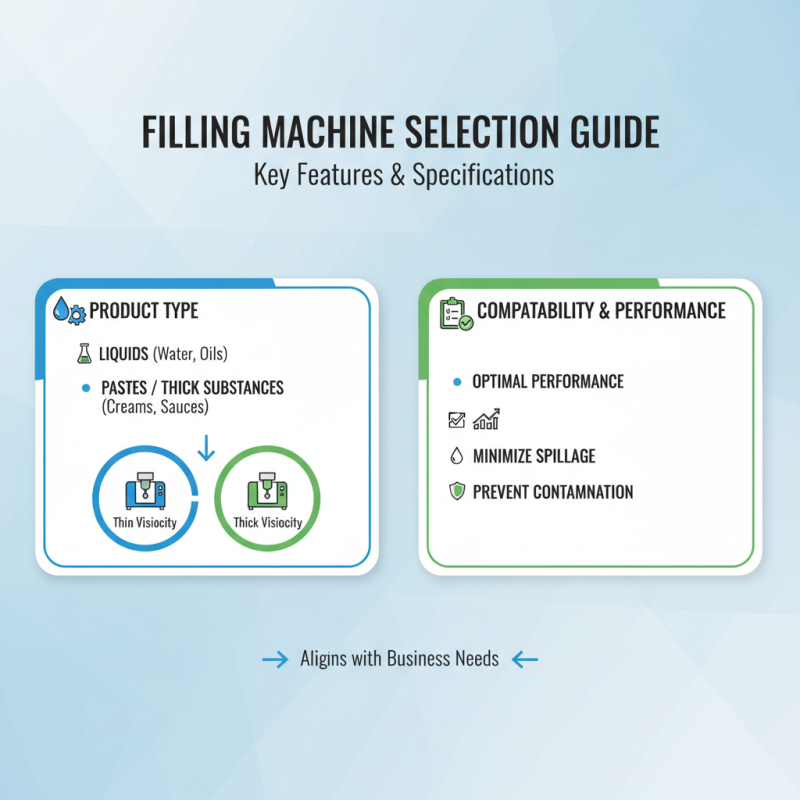

Evaluating Key Features and Specifications of Filling Machines

When selecting a filling machine, it is crucial to evaluate key features and specifications that align with your business needs. First, consider the type of product you will be filling. Different machines are tailored for various viscosities and consistencies, ranging from liquids like water to thick pastes. Assessing the machine's compatibility with your product ensures optimal performance and minimizes the risk of contamination or spillage.

Next, focus on the machine’s production speed and filling accuracy. High-speed machines are essential for businesses with large production demands, while precise filling is vital for maintaining product quality and adhering to regulations. Look for machines that offer adjustable filling volumes and can handle diverse bottle sizes, as flexibility can enhance your operational efficiency. Additionally, consider the ease of maintenance and the availability of automation features, which can further streamline your production process and reduce manual labor costs.

Comparing Costs and Budget Constraints for Filling Machine Options

When selecting a filling machine for your business, understanding costs and budget constraints is essential to making a well-informed decision. Initially, it is crucial to assess your production volume and the type of products you intend to fill. This assessment will help you determine whether a simple, manual machine suffices or if a more complex, automatic solution is warranted. The initial purchase price is just one aspect to consider; the long-term operational costs, including maintenance, labor, and potential downtime, should also be factored into your budget.

In addition to the cost of the machines themselves, it’s important to account for any additional expenses that may arise, such as accessories and parts necessary for optimal operation. For instance, if you choose a machine that requires specific consumables or has a steep learning curve for operators, these factors will add to the overall investment. Budgeting for training and any operational modifications will provide a clearer picture of the total cost associated with your choice. Ultimately, aligning your filling machine selection with your financial capabilities and operational goals ensures a smooth integration into your production line, avoiding future complications and financial strain.

Cost Comparison of Different Filling Machines

This chart compares the costs associated with different types of filling machines essential for evaluating budget constraints when selecting the right machine for your business needs.

Identifying Reliable Suppliers and Service Providers for Filling Machines

When selecting a filling machine, identifying reliable suppliers and service providers is crucial for ensuring the longevity and efficiency of your operations. According to a recent industry report by Smithers Pira, the global packaging machinery market is projected to reach $50 billion by 2027, highlighting the competitive landscape. As a business owner, aligning with reputable suppliers who offer comprehensive technical support and after-sales service can enhance your operational success and minimize downtime.

Tips for finding reliable suppliers include assessing their experience and specialization in your industry. Look for companies with a solid reputation and positive customer reviews. Engaging in industry forums and seeking recommendations from peers can provide insights into the performance of potential suppliers. Additionally, consider visiting suppliers’ facilities to observe their processes firsthand and gaining a better understanding of their capabilities.

Moreover, evaluating the supplier's ability to provide timely service and maintenance is essential. According to a report from the Packaging Machinery Manufacturers Institute (PMMI), 60% of machinery failures are due to inadequate maintenance. Ensure that your chosen provider offers robust service agreements that outline response times and preventative maintenance practices. This proactive approach can significantly extend the lifespan of your filling equipment and improve overall productivity.